I got a letter from my friend Alex in LA, he writes:

"There's a thousand "custom" drums shops out there right now, but they all seem to be using the same keller shells and hardware from egodrumlugs.com, Sure, custom paint, and a special badge, wooo hooo. so is that really custom at all? "

Great question!!

Well to answer your question: Yes and no. They are going to be as custom as you make them. Many times what makes them custom are things that you don't see. I'm sure we have all heard someone say "It's the craftmanship man!" The minor details are the things that can set a custom kit apart from mass produced ones.

Custom drum companies have very limited options when it comes to going into business as far as shells are concerned. They can invest thousands of dollars into the proper machines to make their own shells, then deal with getting the proper permits to go out and log for the best wood. It's a lot easier said than done. Or they can purchase customizable shells from Keller, Anderson, or any other shell maker who deals with the public.

Now when we hear "Keller" shells, we think of SJC Drums, Truth Drums, Darkhorse and all of those other companies that came out after the early 2000's boom of Warped Tour drummers. Don't forget that companies like OCDP and Pork Pie had been doing custom Keller Shell kits for nearly a decade by the time the new wave of Keller Shells hit the market. And, don't forget that DW used Keller shells until the late 90's!

Keller shells are awesome and sound great. What makes them custom, depending on the company, can be a number of things.

First, the bearing edge:

Two common bearing edge styles are the 45 degree and the 30 degree.

The 45 degree is sharper and typically is paired with a sharp bevel. OCDP is famous for having a 45 degree edge with a bevel that looks like a half pipe. It's sharp and narrow. Think of this next time you are checking out drums in a drum shop and try to identify what kind of bearing edge is on the drum you are playing.

The 30 degree bevel is flatter and rounded off typically. These edges are indicative of mostly vintage drums, as well as Yamaha. They usually have a warmer tone.

Reinforcement hoop?

See those things on the inside of the shell? Those are called "Reinforcement Hoops."

Reinforcement hoops are used for cutting out unwanted overtones, adding shell durability, defining a drum's tonal note, and looking pretty dang cool!

Drums that you will usually see with a reinforcement hoop are WFL, DW Collectors Series, Pearl Reference, and some custom kits.

Plies

Many companies are ordering hybrid shells and in many different ply configurations.

For instance, Tama made the Birch Bubinga drum very famous or Pearl's Reference kit features different wood configurations in every drum!

Now you can order much more than just a maple drum from drum shell manufacturers.

The number of plies your drum has will also affect your tone. The thinner the shell, the lower the tone. The thicker (more plies you have) the higher the tone. Think of it in terms of how much room is left inside of the drum.

Less room=higher pitch, More room=lower pitch.

Vents

Drum vents are a cool way to dial in your sound and serve as another way drum companies can customize your kit. You can order special shaped vents from OCDP or Pork Pie, they aren't cheap though!

You can order standard inch, half inch, or smaller vents from most custom drum companies.

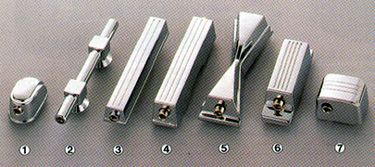

Hardware

Hardware is an important part of a kit but is also pretty limited to designs that already exist. It is difficult to make your own hardware, and since most metal working has been outsourced to Taiwan and China, it's more cost effective to purchase already existing designs from websites like Drum Factory Direct or Ego Drum Lugs. Many companies won't sell lug casings because people will counterfeit whole kits.

The color and style of hardware is what makes many custom drum companies stand out.

Hoops

Extended bass drum hoops, different colored hoops, or wood hoops can change the tone and look of your drum kit!

Finishes

A drum finish can make or break a drum kit.

There are three main types of drum finishes: wrap, lacquer or finished ply.

The two most common are a wrap or a lacquer.

Wraps:

Something is wrapped around the shell. Wraps have a bad reputation of being cheap. They are actually some of the nicest drums that I have seen, but also some of the most hideous.

Common wraps are:

Sparkles

Stripes

Designs

Solid Colors

Animal Prints

Tribals

etc

Check out Precision Drum Company they usually have the nicest wraps and typically sell to custom companies.

Lacquers

A lacquer is when a drum is actually painted. They use laquer paint right on the shell!

DW is a good example to look at when considering a laquer finish.

Many people lacquer clear coats over the natural wood grain. Some people prefer a lacquer paint finish similar to a car finish. Lacquer solid paint colors are rich and similar to the style that vintage cars look, with a "hard candy finish"

Badges and the Resonant Drum Head

Style is definitely a factor when ordering a custom drum kit. You may say it's not, but it has something to do with it. Buying a custom drumkit is awesome and something to be proud of, it's like joining a club. You better show off those badges and front heads with pride!

Things to remember when ordering a custom kit:

They are expensive! Don't think you are getting ripped off. It takes a lot of time to order the right stuff and put it together. Also, they don't get the same pricing that the big guys get on parts and heads. They're paying close to market on all of the parts, not pennies on the dollar.

They take a long time! Typically it's only a few people who make these kits. Even at DW, one of the worlds largest companies, it's only one facility and a handful of people who do each job. If you placed an order for a custom kit today you probably won't see it for about a year.

They resell for 1/4 or less of what you pay! I am not saying this to discourage people from buying custom drums, infact I encourage that you do. I am saying that you put a lot of time customizing your kit to your specs. Not everyone wants a 28x28 kick drum with an 18x20 floor tom in orange glass glitter, but you did. Whatever it is that you order, own it.

Some custom companies that I like

Ford Custom Drums

And so many more, I could be here all day.

If you have your own question for me about drums or drumming please send me an email!

Do you have a question that you have always wanted to ask at a drum shop but didn't?

Ask me!

No comments:

Post a Comment